About Us

Nobble Cables is an independent Designer and Manufacturing Company of Mechanical Control Cables, Engineering Fabricated as well as Machining Parts for various applications at various sectors.

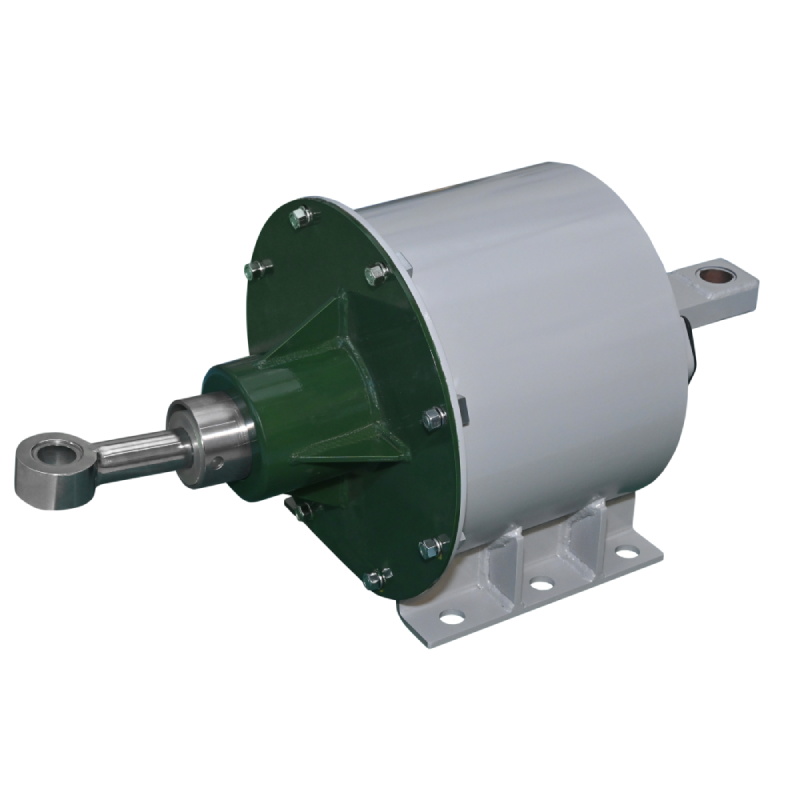

On every wagon fitted with air brake system one brake cylinder is provided for actuating the brake rigging for the application and release of brakes. During application stage the brake cylinder receives pneumatic pressure from the auxiliary reservoir after being regulated by the distributor valve.

There after the brake cylinder develops mechanical brake power by outward movement of its piston assembly. To transmit this power to the brake shoe, the push rod of piston assembly is connected to the brake shoe through a system of levers to amplify and transmit the brake power. During release action of brakes, the compression spring provided in the brake cylinder brings back the rigging to its original position. The cylinder body is made out of sheet metal or cast iron and carries the mounting bracket, air inlet connection, ribs and flange. To the cylinder body, a dome cover is fitted with the help of bolts and nuts.

The dome cover encloses the spring and the passage for the piston trunk, which is connected to the piston by screws. The piston is of cast iron having a groove in which piston packing is seated. Piston packing of rubber material which is of oil and abrasion resistant and unaffected by climatic changes. It is snap fit to the piston head and has self-lubricating characteristic which ensures adequate lubrication over a long service period and extends seal life considerably The piston packing also seals the air- flow from the pressure side to the other side and is guided by the wear ring. The wear ring prevents the friction between cylinder body and the piston head. The piston sub assembly incorporates a push rod, which can articulate and take minor variations in alignment during fitment/operation.